SUGGESTED APPLICATIONS

- Book Covers

- Pocket Folders

- Consumer Product Boxes

- Ad Specialties/Premiums Specialty Packaging

- Crack and Peel Labels

- Dry Erase Surfaces

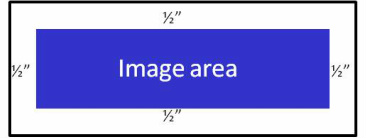

IMAGE LAYOUT

For one-sided lamination, the image area needs to be at least 1/2 inch from the edge of the sheet on all four sides to allow for overlapping of the sheets as they are being fed into the machine and to be able to properly separate the sheets from one another. Image area is anything the press puts on the sheets including varnish and aqueous coating.

LAMINATING MATERIAL THICKNESS

- 1.2 mil

- 1.3 mil

- 1.5 mil

COMMON LAMINATE MATERIALS

- Nylon Gloss - high gloss, counteracts moisture that causes curl

- Nylon Matte - dull matte finish, counter acts moisture that causes curl, scratches easy

- Polyester Gloss - high gloss, durable and scratch resistant

- Polyester Satin - medium gloss, with excellent color consistency

- Polyester Matte - low gloss, durable and great for readability; mutes colors

- Polyester Glueable/Stampable Gloss - compatible with foil stamping, printing, UV coating, and glueing

- Polypropylene Gloss - softer high gloss films that folds easily

- Polypropylene Matte - soft dull matte; folds easily; scuffs easily

- Polypropylene Matte Scuff Free - soft dull matte, folds easily, resists scuffing and scratching